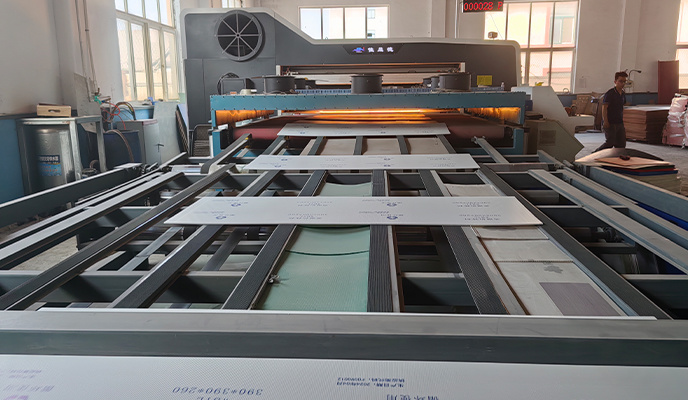

Stone plastic carton hd printing production line

Classification:

Equipment

Efficient

Energy Saving

Stable

Product description

|

|

|

|

Step1 Independent Leading Edge Feed Extended paper feeding (can be arbitrarily set according to needs), Reducing the pressure-free cardboard; |

Step2 Printing Unit The whole process suction feed paper transfer system can realize full plate and solve the problem of flat printing of stone plastic Carton |

|

Parameter |

TOPSOEED |

TOSPEED |

TOSPEED |

TOSPEED |

TOSPEED |

TOSPEED |

TOSPEED |

|

|

Max production |

300 |

280 |

250 |

230 |

180 |

180 |

180 |

|

|

Max cardboard |

900*200 |

900*2400 |

1200*2400 |

1200*2800 |

1600*2400 |

1600*2800 |

1600*3200 |

|

|

Min cardboard |

260*600 |

260*600 |

300*600 |

300*600 |

450*600 |

450*600 |

450*600 |

|

|

Paper size for intermittent feeding(mm) |

1200*2000 |

1200*2400 |

1500*2400 |

1500*2800 |

2000*2400 |

2000*2800 |

2000*3200 |

|

|

Max printing area(mm) |

900*1960 |

900*2360 |

1200*2360 |

1200*2760 |

1600*2360 |

1600*2760 |

1600*3160 |

|

|

Thickness of standard printing plate(mm) |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

|

|

Min slotting distance |

Slotting typeR (mm) |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

|

Slotting typ L (mm) |

230*65*230*65 |

230*65*230*65 |

230*65*230*65 |

230*65*230*65 |

230*65*230*65 |

230*65*230*65 |

230*65*230*65 |

|

|

Min slotting distance |

Slotting type R (mm) |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

130*130*130*130 |

|

Slotting type L (mm) |

230*65*230*65 |

230*65*230*65 |

230*65*230*65 |

230*65*230*65 |

230*65*230*65 |

230*65*230*65 |

230*65*230*65 |

|

|

Max slotting depth(mm) |

250 |

250 |

300 |

300 |

400 |

400 |

400 |

|

Pre-sales

● Products features and application introduction

● Recommend suitable processing technology

● Offer information consultacny

● Offer testing methods and production technology standard Machinery Production

● Offer the machinery installation required conditions

● Could change the solution modification without notice

● Study and solve technology situation and materials formulation together

After-sales

● Offer installation and worker training

● Establish and record customer document

● Offer spare parts to assure the machine maintenance and stable production

● Offer necessary technique support for the new machinery

● Regularly visit customers and collect feedback

● Promise of one year quality guarantee, lifetime guarantee of machine maintenance

RECOMMENDED EQUIPMENT